The production of fabric textiles includes a variety of materials including thread, yarn, and fibers. Typically, the individual material strands are fastened to the machine and then are guided through the manufacturing process with a specific tension.

The tension of the textile is extremely important to produce a quality product. Imperfect tension can cause a multitude of production issues. Tensitron Tension Meters help to avoid manufacturing tension issues and ensure the tension remains constant so the production process goes smoothly.

The impacts of improper tension (under and over tension) and how to prevent them.

Under tensioning causes drop-stitching defects:

Irregular or under tension on the material will cause the material to be too loose when fed into the machine. Under tension will cause drop-stitching defects to the uniformity of fabric resulting in inferior quality. Additionally, if the tension is too loose, the production process will suffer with possible clogging of the machine which will lead to increased production time.

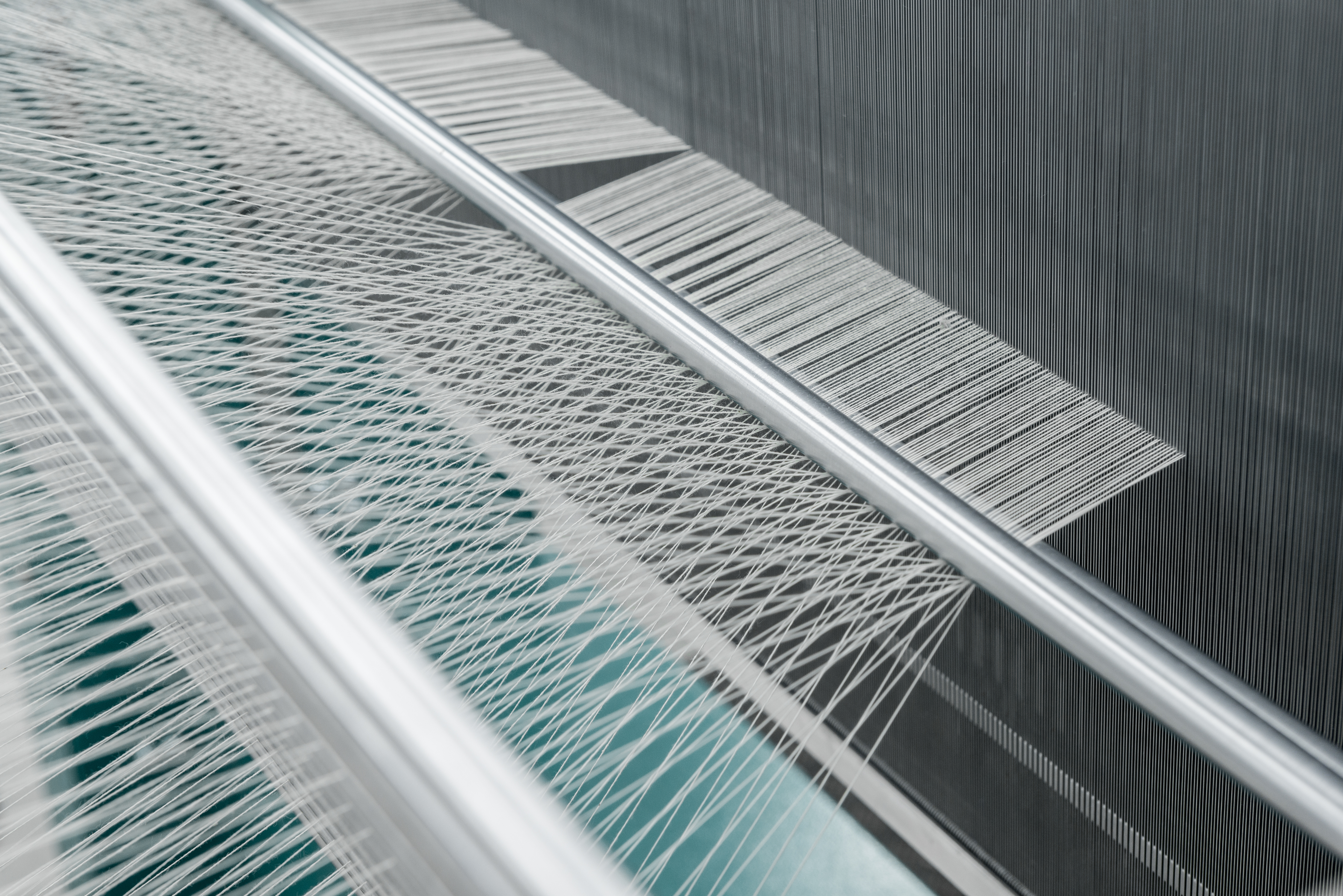

Stretched Yarn Attached to Machinery in a Textile Factory

To prevent drop-stitching defects and clogging of machinery – Necessary monitoring of the material during the manufacturing process, which includes managing the tension of the material, is required. Tensitron Meters will help with spot-checking or continuously monitoring the tension to ensure a quality product.

Over-tensioning causes broken ends.

Due to excessive tensioning, the material will brake during the manufacturing process and create broken ends. Broken ends appear as equidistant (at equal distances) horizontal lines in the final product. Even one broken end will affect the production process and the quality of the product.

To prevent broken ends and horizontal line defects – The best way to solve this issue is to maintain the proper tension on the material. Spot checks or install a continuous monitoring system will help monitor tension on the material.

Overall Importance of Tension Testing in Textile Manufacturing:

Without having defined tension parameters on the material, defects can occur at any moment. Tension testing should be part of the textile manufacturing process to monitor for continuous and constant tension. The result of this monitoring for tension will allow the machine to run as efficiently as possible, absent any other manufacturing issues.

So, before production, consider tension testing in an agreed-upon system to avoid fabric defects and ensure your product meets company and customer standards.

Why choose Tensitron for the textile industry?

Tensitron has multiple options for Hand-held and Mounted Tension monitoring devices for static and continuous tension monitoring. The Tensitron Meters will check tensions on yarn and narrow fabrics for textile manufacturing purposes. Tensitron Meters help to ensure process and quality control in manufacturing and testing environments.

TX-1 Series Tension Meter is designed for yarn and materials. Tension Meter tests tension from 0 to 5,000 grams with a full-scale accuracy of +/-1%.

WX-1 Series Tension Meter is ideal for comprehensive, flat web/ fabric materials. Test in a range of 0.5 lbs. to 1,000 lbs. with +/- 2% accuracy.

Tensitron tension sensors can be mounted and convert the tension to a reliable signal to a remote display with a high-speed recording or automatic tension control. The mounted sensors can be customized for your specific material or environment. The typical range is from 1/10th gram to 500 lbs. Tensitron transducers can be customized to meet your needs.

TX, WX meters, and Tension sensors are also used for various applications and can be customized to roller-type manufacturing processes or directly incorporated into the rollers.

Tensitron Meters are here to help to create quality textile products. For more information, please check the Tensitron website at www.Tensitron.com

Thanks!