Tension testing is performed on cable railing during the installation process for both residential and commercial settings. The tension of the cable must pass rigorous standards for safety.

During the installation, the tension of the cable must be tight enough to withstand a certain amount of force. The post system that supports the cables is a major contributing factor to the amount of tension the cable can withstand.

The Tension of Cable:

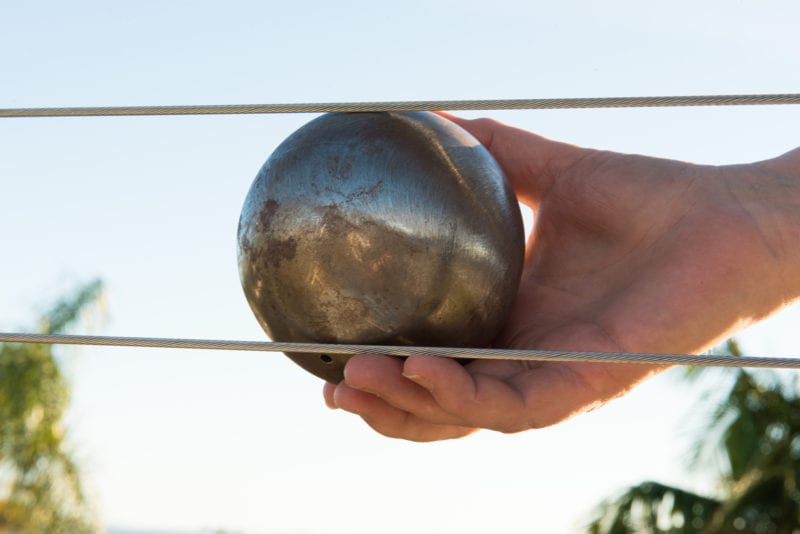

The metal cable, which is usually stainless steel, is drawn horizontally in numerous rows. The combination of the spacing of the rows and the tension on the cables should not allow a 4” sphere to pass through the cables.

Generally, the minimum tension requirements for a railing system require the system to withstand uniform loads of 50 pounds applied both horizontally and vertically. Specific State codes determine the exact tension requirement for the railing use.

The Spacing of Posts

Commercial Application: Per the International Building Code (IBC), manufactured deck railing posts should be spaced no more than 8 feet apart and withstand up to 200 lbs. of pressure from any direction at any single point.

Image: Indicating 4” sphere rules spacing between cables.

Residential or non-commercial space: Per the International Residential Code (IRC), which is generally adopted by most U.S. cities, decks more than 30 inches above the ground require railings at least 36 inches in height measured from the deck’s surface to the top of the rail. Cable railing posts can be maximum of 4 feet apart; however, it is recommended to check local building codes beforehand.

The Deck Railing System:

At the minimum, the cable and the posts together must be strong enough to withstand uniform loads and support concentrated loads of 200 pounds applied in any direction. As said above, the cables, supported by the posts, cannot allow a 4” sphere to pass through the cable plane.

Why is tension testing required?

Safety is the primary reason to have the tension on the cables tested. Tension testing ensures that each cable running from each post is tightened to have equal tension to support concentrated loads. If the tension is tight enough, then a 4” sphere (dimension of small objects) cannot penetrate the line of the cables.

Maintaining enough tension to prevent cables from moving or stretching is required to pass IBC and IRC inspections.

Why Tensitron Meters:

We recommend the Tensitron CX tension meter for tension testing on the cables in the railing system for both commercial and noncommercial uses. The most common sizes of cable used are 1/8″ and 3/16″ stainless steel. Tensitron CX is perfect for the job.

Tensitron CX tension meters can also measure the tension of cables in various other applications, including catenary systems, elevator maintenance, telecommunications cables, guy wire, zip lines, theater rigging, and more.

Tensitron offers many types of meters to meet the customers’ needs for testing tension. Tensitron ensures quality and functionality. Click here to learn more.