Safely install or monitor cables, wire rope, and other materials with a Tensitron CX-1 tension meter. Achieve consistent tension to avoid mechanical stresses, and minimize the risk of damage to cables or objects.

Why is Cable Tension Important?

Proper tensioning of cables or wire rope is an important part of the installation of your materials. Checking cable tension ensures that cables or wire ropes are consistently, correctly tensioned to protect, support, or anchor objects. If tension is too low, cables will not provide support; too high, and cables may break or recoil.

How can you check tension levels on your materials? A tension meter can be used to precisely determine the exact tension you require. Tension meters are clamped onto a cable or wire rope to measure the deflection of the material and then convert the deflection into tension. Accurate tensioning allows the safe installation or monitoring of cables, wire ropes, and other materials.

Why choose the CX-1 tension meter? The CX-1 tension meter is specifically designed to measure tension on cables and wire ropes. Using the CX-1 tension meter is as simple as engaging it on the cable, storing the tension reading, and removing the meter from the cable. One person working alone can check tension in seconds. No reference or conversion charts are needed.

With the Tensitron CX-1 you can precisely measure tension on flexible cables from 1/16 inch to ¾ inch in diameter and 20 to 2000 lbs. Up to 10 materials can be calibrated to the instrument. Advanced features include continuous or single-point data storage, selectable units (lb., kg, or daN), and onboard data statistics.

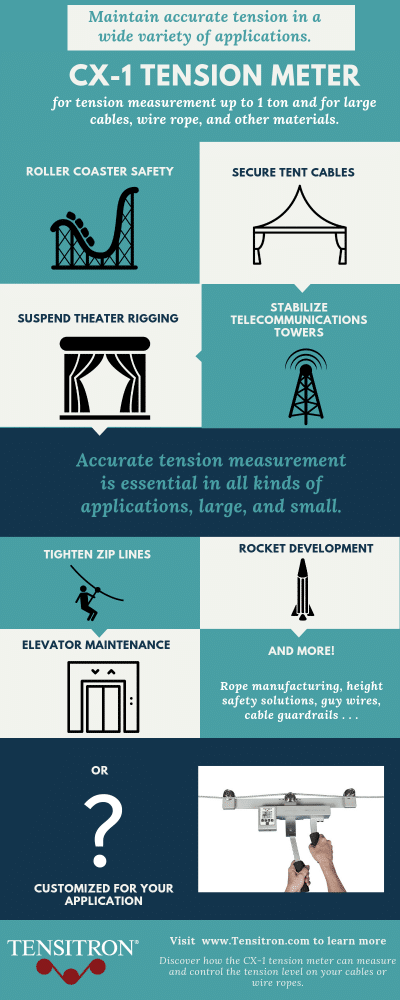

Will a CX-1 tension meter work for your application? The CX-1 is used in many industries worldwide to verify tension. Some common applications include cable guardrails, guy lines, overhead wires, elevators, and telecommunications cables. Take a look at some of the uses of the instrument below. Click on the graphic to contact us and discover how the CX-1 will work for your application.